example presented

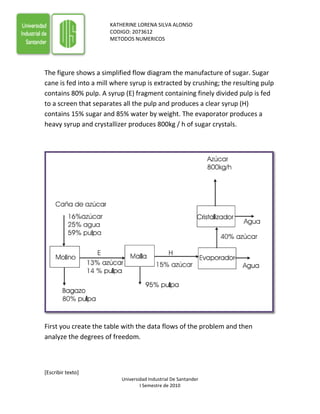

- 1. KATHERINE LORENA SILVA ALONSOCODIGO: 2073612METODOS NUMERICOS-705485-607695<br />The figure shows a simplified flow diagram the manufacture of sugar. Sugar cane is fed into a mill where syrup is extracted by crushing; the resulting pulp contains 80% pulp. A syrup (E) fragment containing finely divided pulp is fed to a screen that separates all the pulp and produces a clear syrup (H) contains 15% sugar and 85% water by weight. The evaporator produces a heavy syrup and crystallizer produces 800kg / h of sugar crystals.<br />First you create the table with the data flows of the problem and then analyze the degrees of freedom.<br />FEDGHJKLMAgua25?73?85100601000Azucar16?13?150400100pulpa5980149500000<br />NUMBER OF UNKNOWNS: <br />The flow of the currents F, E, D, G, H, J, K and L and also the four compositions listed in the table. A total of 12 unknowns.<br />Along with the material balances have restrictions on the amount of the compositions to be 100%. There are two restrictions for such flows D and G. A total of 12 EQUATIONS.<br />DEGREES OF FREEDOM <br /> 12 - 12 = 0. Then the problem is well posed.<br />BALANCES IN THE MILL<br />0.16 · F = 0.13E + XD,azD<br />0.25 · F = 0.73E + XD,agD<br />0.59 · F = 0.14E + 0.8D<br />1 = 0.8 + xD,az + XD,ag<br />BALANCES IN THE CRYSTALLIZER<br />0.4K = M; K = 800/0.4 = 2000kg/h<br />K = M+ L; L = 2000 − 800 = 1200kg/h<br />BALANCES IN THE EVAPORATOR<br />0.15H = 0.4K; H = 0.4 · 2000/0.15 = 5333.3kg/h<br />H = J + K; J = 5333.3 − 2000 = 3333.3kg/h<br />BALANCES TO THE SCREEN<br />0.13E = xG,azG + 0.15H<br />0.14E = 0.95G<br />E = H + G; E = 5333.3 + G<br />In the last two equations gives G and E: <br />G = 921.8 kg / h<br />E = 6255.1kg / h.<br />Therefore it is in the first equation:<br />xG,az = 0.13 · 6255.1 − 0.15 · 5333.3/921.8 = 0.0143 1.43%<br />The rest of the current G: 100-95-1.43 is water.<br />The fraction of water is: 3.57%.<br />Given the current composition of G are resolved to the mill resulting balances:<br />F=19659kg/h;<br />D=13404kg/h;xD,az = 0.174<br />The table is finally compositions:<br />FEDGHJKLMAgua252.6733.5785100601000Azucar1617.4131.43150400100pulpa5980149500000<br />Applying the proposed program with the Gauss method records the following logical sequence:<br />